How Deep to Bury Liquid Tight Conduit

Learn the proper depth requirements for burying liquid-tight conduit to ensure safe and code-compliant electrical installations.

The machinery industry relies heavily on cables, but improper cable management can lead to safety hazards, equipment damage, and costly downtime.

Using the wrong cable accessories, such as cable glands and terminals, can compromise the integrity of your electrical systems. Confusion about the differences between these components makes it difficult to select the right ones for the job.

In this post, we’ll clarify the key distinctions between cable glands and cable terminals, including their primary functions, construction, ideal environments, installation methods, protection capabilities, materials, and common applications.

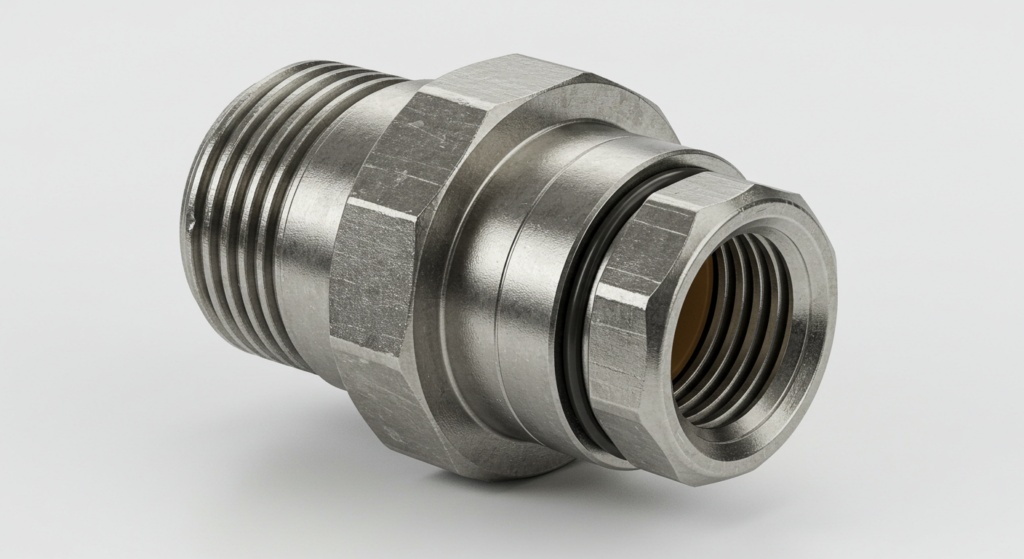

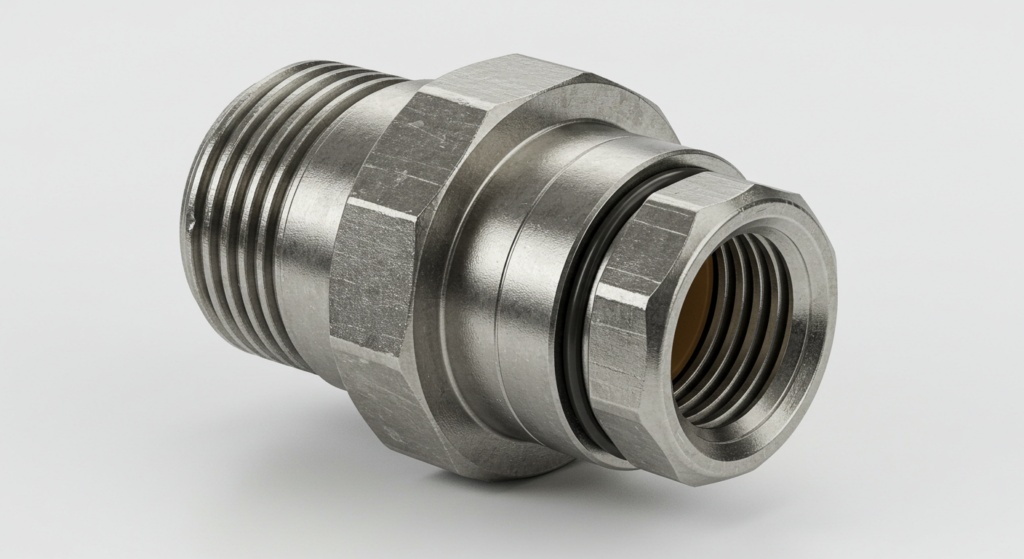

A cable gland, also known as a cable connector, is a device designed to attach and secure the end of an electrical cable to a piece of equipment. Cable glands provide strain relief and protect against dust, dirt, and liquid ingress, as well as ensuring the cable’s internal wiring remains safely connected. They are commonly constructed from brass, stainless steel, plastic, or aluminum, and consist of a body, sealing ring, and locking nut that clamps the cable securely in place.

Cable glands are used in a variety of environments, including hazardous areas, industrial settings, and outdoor installations. They are typically installed by inserting the cable through the gland body and tightening the locking nut, which compresses the sealing ring around the cable jacket. This creates an environmental seal and prevents the cable from being pulled out.

A cable terminal, also referred to as a wire terminal or crimp terminal, is an electrical connector attached to the end of a wire or cable that enables it to be securely connected to a terminal block, ground stud, or another termination point. Cable terminals consist of a barrel that is crimped onto the conductor and an insulated sleeve or shroud that covers the barrel and part of the cable insulation.

The primary function of a cable terminal is to provide a secure, low-resistance connection between the wire and the termination point, facilitating the efficient transfer of electrical current. They are widely used in electrical and electronic systems, including automotive wiring, industrial control panels, and home appliances.

Cable Gland: The main function of a cable gland is to provide a secure entry point for a cable into an enclosure or piece of equipment while protecting the cable from damage and environmental factors.

Cable Terminal: The primary purpose of a cable terminal is to create a secure, low-resistance connection between the end of a wire or cable and a termination point, such as a terminal block or ground stud.

Cable Gland: A cable gland typically consists of a body, sealing ring, and locking nut. The body has threads that allow it to be screwed into the equipment, while the sealing ring and locking nut work together to grip the cable securely.

Cable Terminal: A cable terminal comprises a barrel that is crimped onto the conductor and an insulated sleeve or shroud that covers the barrel and part of the cable insulation. The barrel may have a ring, fork, spade, or pin shape, depending on the terminal type.

Cable Gland: Cable glands are designed for use in various environments, including hazardous areas, industrial settings, and outdoor installations. They protect the cable and equipment from dust, dirt, moisture, and other environmental factors.

Cable Terminal: Cable terminals are used in a wide range of electrical and electronic systems, such as automotive wiring, industrial control panels, and home appliances. They are not specifically designed for environmental protection.

Cable Gland: Installing a cable gland involves inserting the cable through the gland body and tightening the locking nut, which compresses the sealing ring around the cable jacket to create an environmental seal and prevent the cable from being pulled out.

Cable Terminal: Cable terminals are attached to the end of a wire or cable by crimping the barrel onto the conductor using a specialized crimping tool. The insulated sleeve is then slid over the barrel to provide insulation and strain relief.

Cable Gland: Cable glands provide strain relief and protect the cable from damage caused by tension, twisting, or bending. They also prevent the ingress of dust, dirt, and liquids, maintaining the integrity of the electrical connection.

Cable Terminal: Cable terminals offer limited protection against strain and environmental factors. Their primary focus is on creating a secure electrical connection rather than providing comprehensive protection for the cable.

Cable Gland: Cable glands are commonly made from materials such as brass, stainless steel, plastic, or aluminum, depending on the application and environmental requirements.

Cable Terminal: Cable terminals are typically constructed from conductive materials like copper or brass and may be plated with tin, nickel, or silver for improved conductivity and corrosion resistance.

Cable Gland: Cable glands are used in various applications where cables need to be securely fastened to equipment or enclosures while being protected from environmental factors. Examples include industrial machinery, outdoor telecommunications equipment, and hazardous area installations.

Cable Terminal: Cable terminals are widely used in electrical and electronic systems to create secure connections between wires and termination points. Applications include automotive wiring harnesses, industrial control panels, household appliances, and electronic devices.